Plant.One

Well-known member

Thank you Orkan at Primal Rights for selecting me to participate in your new product review.

As someone who doesnt currently participate in precision rifle disciplines, honestly without being selected for this trial your product would have been out of my shopping budget for a primer seating tool so i would have missed out on the opportunity to use your fantastic product. Not that i feel its specifically over priced, just i dont currently have a use for the level of precision your tool allows and therefore no need to look to a product on this level at this time.

Quick review on a scale of 1-10

Overall: 9/10

Packing: 10/10

Presentation: 10/10

Fit and Finish: 9/10

Ease of installation and initial setup: 9/10

Overall ease of use: 10/10

would i recommend this product to a friend - yes, absolutely. It allowed me to easily and consistently seat primers once it was setup and operational.

Like the others who received this tool, mine came well packaged, if not overpacked! The likelihood of it receiving shipping damage are nearly non existent - short of being run over or some other extreme negligence on the part of the shipper anyway. Even a UPS Drop Kick wouldnt likely harm this packaging.

Getting the CPS Lite mounted to my press was simple, it locked into my Lee quick change bushing with ease and the lock ring was easy to manage.

Initally getting the seating depth collar adjusted was a bit tricky, but part of that i have to admit to a silly user error issue - i had grabbed some brass that still needed to be swaged and the primer pockets were out of spec. The directions clearly state to use brass with a specific primer pocket spec for both large and small primers.

Once i switched to properly swaged brass - i had it lined up with my hand seated test primer, adjusted and locked in with the very next try!

50 pieces of finished brass. I primed a total of 100 pieces of 300 blackout.

Primers seated effortlessly compared to my other on press experience, but the press does seem to have more leverage when you're priming on the ram upstroke and not a forward push on the handle at the bottom of the ram downstroke.

however with the primer depth stop in play it made maintaining a consistent .004" primer seating depth simple.

As an unexpected bonus - the primer feed tube appears to be a standard primer pickup/feed tube. As such i was able to use the tube from my Franklin Vibra Prime primer tube filler tubes directly in the primal rights shuttle. No hand popping primers into the pickup/feed tube for me!

Once i got things rolling, i was able to breeze through the 100 pack of primers i had fed into the primer tube against the product instructions

The hardest adjustment to make for me was priming on the upstroke on the press. I do not say that this is a flaw of the tool, just a change that i had to adjust to in getting used to this new tool.

The hardest adjustment to make for me was priming on the upstroke on the press. I do not say that this is a flaw of the tool, just a change that i had to adjust to in getting used to this new tool.

Switching from large to small primer shuttles was very easy and nearly effortless.

Now onto the bad parts. I consider these to be relatively minor, but i did notice them and want to make sure i give equal exposure to what i perceive of both the good and the bad.

Upon unpacking the tool i noticed the first (and only) machining flaw that i found on the tool i received. The handle on the large primer shuttle had a small burr on the tip of the handle. This was sharp. It wasn't large enough to pierce skin, but if it was left in place for repeated use i would think its enough to cause irritation, a blister or a light scrape. However on a tool of this price point, i would expect that a deburring check on a machined handle point would be standard.

here's a video of it scoring paper with a light push

with just a quick touch of the file it was gone.

I assume that this was a simple QC flaw on item i received and not indicative of the quality of the QC on the product line as a whole - unfortunately i've got a good enough relationship with Murphy's Law for this to hold true.

The other thing i noticed when i found a couple out of spec primer pockets, the small rifle primer seating rod crushed into the primer leaving a sharp ring along one edge.

Here are two that smashed in pretty badly.

I've never seen a primer do this before - i've managed to crush primers into the pocket in various ways on the press over the last few years due to a lack of feel compared to hand seating, but never quite like this - and it got me curious.

The instructions clearly state that primer pocket minimum specs should be as follows

Large Primer - 0.2085"

Small Primer - 0.173"

When i measured the diameter of the large and small primer seating rods i got the following measurements

CPS Lite Seating Stem

Large - 0.180"

Small - 0.145"

so for a baseline that puts us respectively at 0.028" smaller than the primer pocket minimum for small and 0.0285" smaller than the large primer pocket minimum dimension.

Compared to the other primer seating tools i own, this is quite a large tolerance - and therefore a lot less of the primer cup supported during the seating process.

here are the measurements of the primer seating stems on the tools i have on hand and their variance from minimum primer pocket min spec

Hornady LNL AP Press

Lg: 0.205" - 0.0035

Sm: 0.171" - 0.002

Lee Safety Prime (On press priming)

Lg: 0.204" - 0.0045

Sm: 0.173 - 0.000

Lee Auto Prime XR

Lg: 0.201" - 0.0075

Sm: 0.170" - 0.003

So while other tools use a tolerance that's only a few thousandth's smaller than the minimum primer pocket, your tool uses a seating stem with significantly less primer cup supported during the seating process.

As you can see from the photo this allowed the primer seating stem to be off center on the primer cup and to show a dominant burr on one side. The primer on the left i had to use a pair of pliers to remove it from the shellholder so part of that shoulder burr was actually worn down removing that brass from the shell holder.

While this variance did not seem to effect proper seating on a correctly sized primer pocket, as soon as i encountered a primer pocket that was a little on the tight side (under min spec) that lack of support really showed itself.

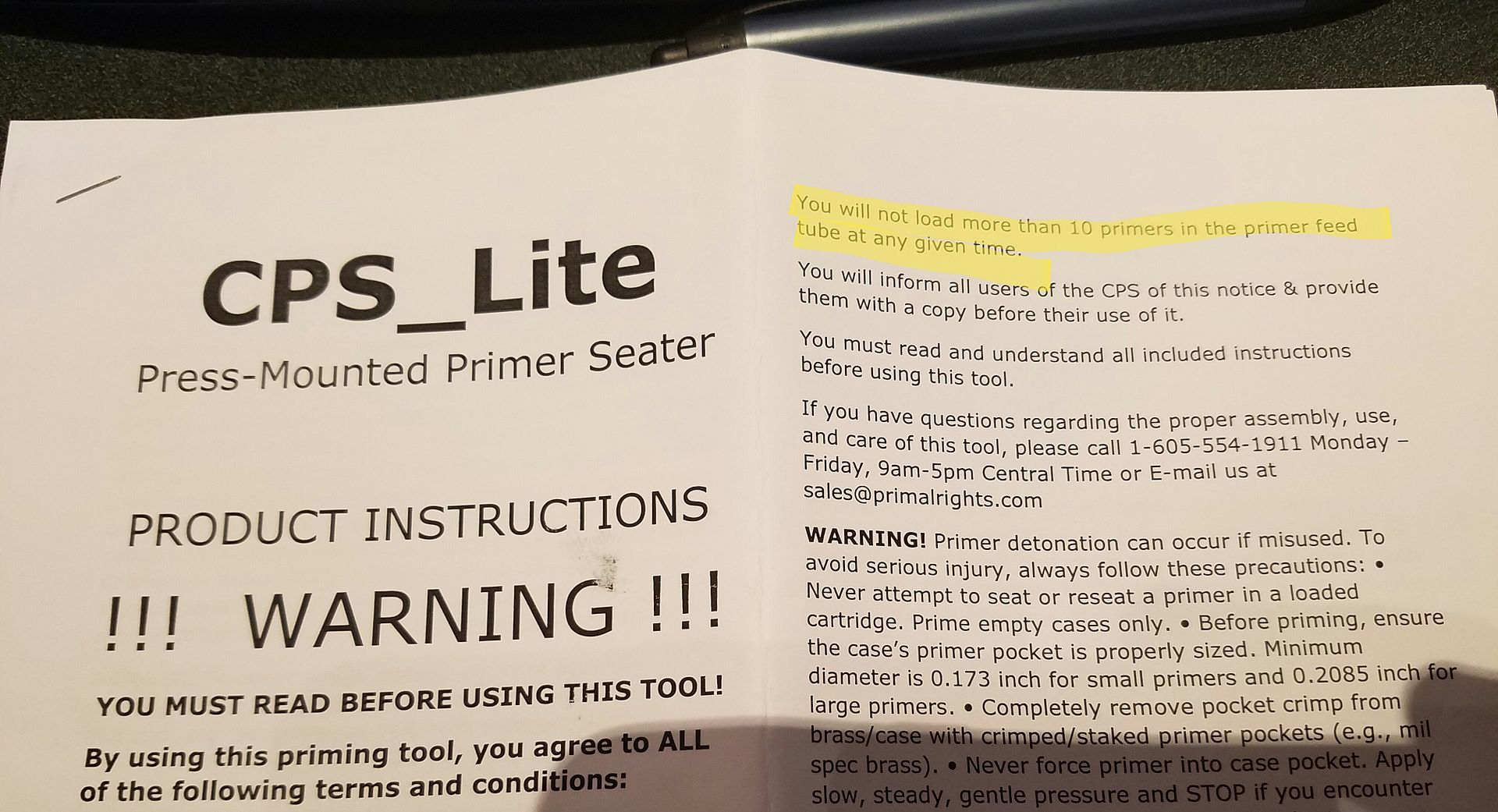

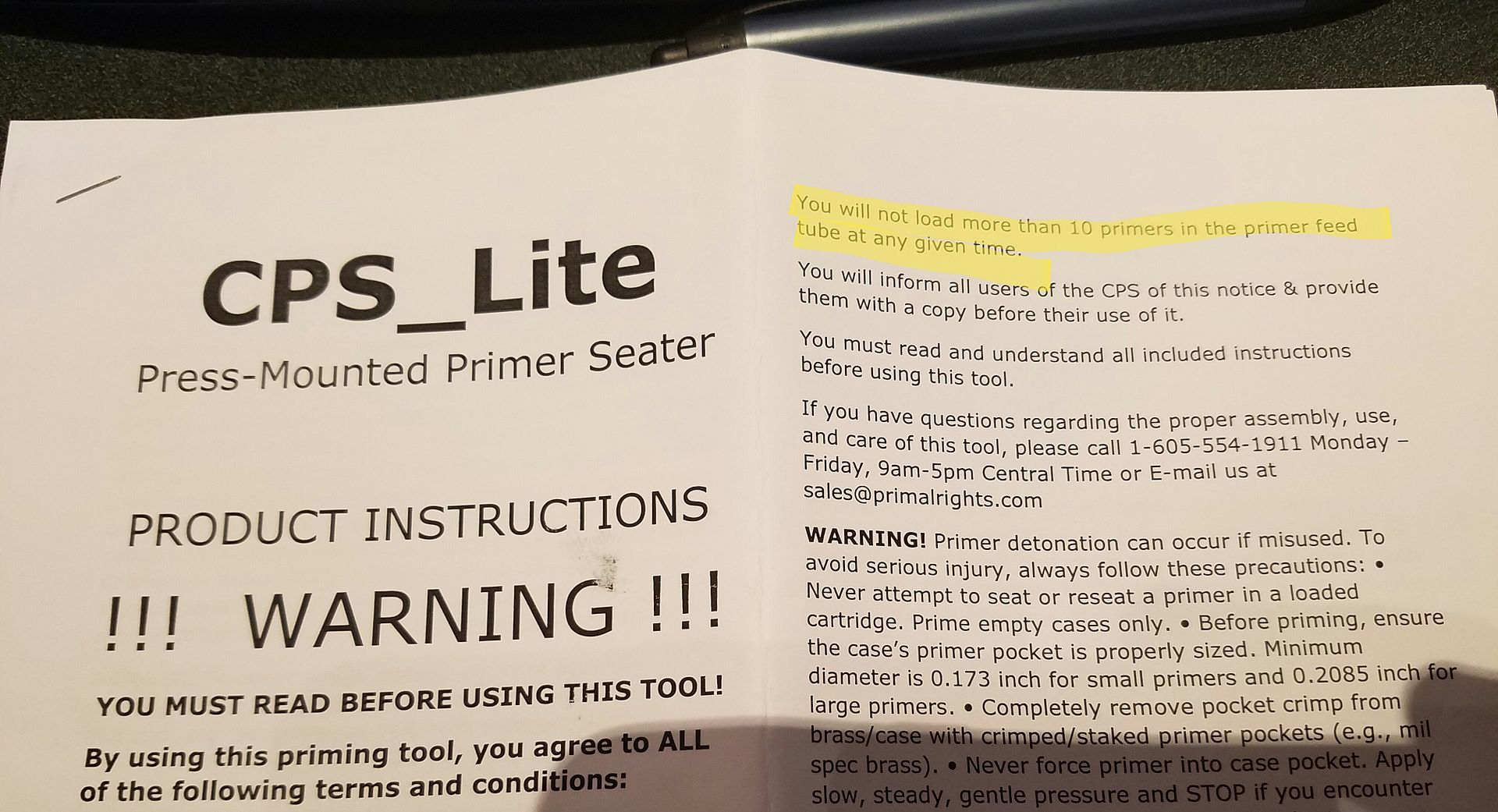

Additionally there was one part of the instructions that i found to be unusual as well. Regarding the primer feed tube, the first page of the CPS lite instructions clearly state

is this a typo and supposed to say 100 primers? Or do you really expect your users to only feed 10 primers into the feed tube at a time? If in fact there is a safety concern when loading more than 10 primers, why do you provide full length primer feed tubes?

Again, overall i give your product a 9/10.

Thank you again for allowing me to review your product and to add this wonderful tool to my reloading tool collection.

--------------------------------------------------------------

as a total side note - holy smokes for cool points on the quality of your business card! I thought when we had our store that our business cards were good - we used to joke that our water resistant cardstock was good enough to use as an algae scraper for our customer's aquariums. Your's top that by a yard or more!

This is similar material that i would expect to find in a shopping rewards card or like a speedway fuel card type of thing.

As someone who doesnt currently participate in precision rifle disciplines, honestly without being selected for this trial your product would have been out of my shopping budget for a primer seating tool so i would have missed out on the opportunity to use your fantastic product. Not that i feel its specifically over priced, just i dont currently have a use for the level of precision your tool allows and therefore no need to look to a product on this level at this time.

Quick review on a scale of 1-10

Overall: 9/10

Packing: 10/10

Presentation: 10/10

Fit and Finish: 9/10

Ease of installation and initial setup: 9/10

Overall ease of use: 10/10

would i recommend this product to a friend - yes, absolutely. It allowed me to easily and consistently seat primers once it was setup and operational.

Like the others who received this tool, mine came well packaged, if not overpacked! The likelihood of it receiving shipping damage are nearly non existent - short of being run over or some other extreme negligence on the part of the shipper anyway. Even a UPS Drop Kick wouldnt likely harm this packaging.

Getting the CPS Lite mounted to my press was simple, it locked into my Lee quick change bushing with ease and the lock ring was easy to manage.

Initally getting the seating depth collar adjusted was a bit tricky, but part of that i have to admit to a silly user error issue - i had grabbed some brass that still needed to be swaged and the primer pockets were out of spec. The directions clearly state to use brass with a specific primer pocket spec for both large and small primers.

Once i switched to properly swaged brass - i had it lined up with my hand seated test primer, adjusted and locked in with the very next try!

50 pieces of finished brass. I primed a total of 100 pieces of 300 blackout.

Primers seated effortlessly compared to my other on press experience, but the press does seem to have more leverage when you're priming on the ram upstroke and not a forward push on the handle at the bottom of the ram downstroke.

however with the primer depth stop in play it made maintaining a consistent .004" primer seating depth simple.

As an unexpected bonus - the primer feed tube appears to be a standard primer pickup/feed tube. As such i was able to use the tube from my Franklin Vibra Prime primer tube filler tubes directly in the primal rights shuttle. No hand popping primers into the pickup/feed tube for me!

Once i got things rolling, i was able to breeze through the 100 pack of primers i had fed into the primer tube against the product instructions

Switching from large to small primer shuttles was very easy and nearly effortless.

Now onto the bad parts. I consider these to be relatively minor, but i did notice them and want to make sure i give equal exposure to what i perceive of both the good and the bad.

Upon unpacking the tool i noticed the first (and only) machining flaw that i found on the tool i received. The handle on the large primer shuttle had a small burr on the tip of the handle. This was sharp. It wasn't large enough to pierce skin, but if it was left in place for repeated use i would think its enough to cause irritation, a blister or a light scrape. However on a tool of this price point, i would expect that a deburring check on a machined handle point would be standard.

here's a video of it scoring paper with a light push

with just a quick touch of the file it was gone.

I assume that this was a simple QC flaw on item i received and not indicative of the quality of the QC on the product line as a whole - unfortunately i've got a good enough relationship with Murphy's Law for this to hold true.

The other thing i noticed when i found a couple out of spec primer pockets, the small rifle primer seating rod crushed into the primer leaving a sharp ring along one edge.

Here are two that smashed in pretty badly.

I've never seen a primer do this before - i've managed to crush primers into the pocket in various ways on the press over the last few years due to a lack of feel compared to hand seating, but never quite like this - and it got me curious.

The instructions clearly state that primer pocket minimum specs should be as follows

Large Primer - 0.2085"

Small Primer - 0.173"

When i measured the diameter of the large and small primer seating rods i got the following measurements

CPS Lite Seating Stem

Large - 0.180"

Small - 0.145"

so for a baseline that puts us respectively at 0.028" smaller than the primer pocket minimum for small and 0.0285" smaller than the large primer pocket minimum dimension.

Compared to the other primer seating tools i own, this is quite a large tolerance - and therefore a lot less of the primer cup supported during the seating process.

here are the measurements of the primer seating stems on the tools i have on hand and their variance from minimum primer pocket min spec

Hornady LNL AP Press

Lg: 0.205" - 0.0035

Sm: 0.171" - 0.002

Lee Safety Prime (On press priming)

Lg: 0.204" - 0.0045

Sm: 0.173 - 0.000

Lee Auto Prime XR

Lg: 0.201" - 0.0075

Sm: 0.170" - 0.003

So while other tools use a tolerance that's only a few thousandth's smaller than the minimum primer pocket, your tool uses a seating stem with significantly less primer cup supported during the seating process.

As you can see from the photo this allowed the primer seating stem to be off center on the primer cup and to show a dominant burr on one side. The primer on the left i had to use a pair of pliers to remove it from the shellholder so part of that shoulder burr was actually worn down removing that brass from the shell holder.

While this variance did not seem to effect proper seating on a correctly sized primer pocket, as soon as i encountered a primer pocket that was a little on the tight side (under min spec) that lack of support really showed itself.

Additionally there was one part of the instructions that i found to be unusual as well. Regarding the primer feed tube, the first page of the CPS lite instructions clearly state

is this a typo and supposed to say 100 primers? Or do you really expect your users to only feed 10 primers into the feed tube at a time? If in fact there is a safety concern when loading more than 10 primers, why do you provide full length primer feed tubes?

Again, overall i give your product a 9/10.

Thank you again for allowing me to review your product and to add this wonderful tool to my reloading tool collection.

--------------------------------------------------------------

as a total side note - holy smokes for cool points on the quality of your business card! I thought when we had our store that our business cards were good - we used to joke that our water resistant cardstock was good enough to use as an algae scraper for our customer's aquariums. Your's top that by a yard or more!

This is similar material that i would expect to find in a shopping rewards card or like a speedway fuel card type of thing.